http://crown-capital-eco.blogspot.co.uk/2013/01/crown-capital-eco-management-biomass.html

Crown Capital Eco Management Indonesia – The heavily forested city of Ketchikan, Alaska, is built on rock and surrounded by water. Every commodity that comes into Ketchikan must arrive by sea or air. The use of fuel oil is problematic for both economic and environmental reasons because the oil must be obtained and refined elsewhere and transported (using additional fuel). What’s more, fuel oil is subject to price instability.

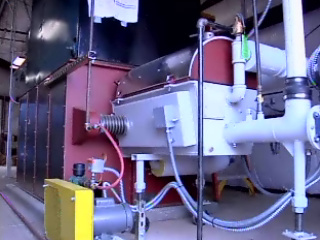

Southeast Alaska Discovery Center in Ketchikan, which provides information to more than a million visitors each year, is the site of a pilot biomass boiler system now coming to life. Two oil-fired boilers serving the 250,000-sq-ft center were replaced with a highly efficient system fueled by local wood. Manufactured by Hurst Boiler & Welding Company Inc., the hot-water boiler was custom-designed to fit within very limited indoor space.

Under the direction of E. Dane Ash, project manager for Tyonek-Alcan Pacific LLC, the biomass boiler system was developed with Hurst representative Gregory W. Smith of Global Energy Solutions Inc. to address environmental concerns, as well as issues related to building space, fuel costs, comfort, reliability, and simplicity of operation.

The new boiler is located on the lower level of the Discovery Center, which requires heating for a minimum of nine months a year. Local wood densified into fuel pucks is delivered to an elevated walking-floor storage bin in a vestibule area built to protect against excessive moisture. (The biomass-fired boiler can burn any wood product with up to 50-percent moisture content.) An auger moves pucks from the storage area to a metering bin and into the boiler. Freezing is not an issue because the walking floor easily breaks up any frozen contents.

The boiler system was designed to highlight how biomass can reduce or eliminate the use of fossil fuels. Visitors can see the boiler operate through specially designed windows. In the hall just outside of the boiler room, the noise level and ambient temperature is consistent with the rest of the building.

Savings

Fuel costs have been cut by two-thirds. The densified pucks are used with almost no residual ash; eventually, however, tree clippings from the Ketchikan walking trails will be ground and fed into the boiler, eliminating the need for transport to a landfill, burning, and other methods of disposal.

The Boiler

The Hurst S100 Series Fire Tube 27 HP Hydronic Water Heating Boiler features a pre-heater to optimize combustion and an underfeed stoker with dry-ash-removal system.

Results

The system easily can be replicated for heat or heat/power generation up to 20,000 kw. In June 2011, Smith served as a keynote speaker for the fifth annual Native American Economic Development Conference in Anaheim, Calif., where he described the initiatives being implemented in Ketchikan and shared success stories of biomass-fired boiler systems installed on institutional campuses and in manufacturing facilities throughout the United States, particularly in challenging and remote locations. Systems include municipal solid waste, as well as woody biomass for steam production and steam to power.

Crown Capital Eco Management Indonesia – The heavily forested city of Ketchikan, Alaska, is built on rock and surrounded by water. Every commodity that comes into Ketchikan must arrive by sea or air. The use of fuel oil is problematic for both economic and environmental reasons because the oil must be obtained and refined elsewhere and transported (using additional fuel). What’s more, fuel oil is subject to price instability.

Southeast Alaska Discovery Center in Ketchikan, which provides information to more than a million visitors each year, is the site of a pilot biomass boiler system now coming to life. Two oil-fired boilers serving the 250,000-sq-ft center were replaced with a highly efficient system fueled by local wood. Manufactured by Hurst Boiler & Welding Company Inc., the hot-water boiler was custom-designed to fit within very limited indoor space.

Under the direction of E. Dane Ash, project manager for Tyonek-Alcan Pacific LLC, the biomass boiler system was developed with Hurst representative Gregory W. Smith of Global Energy Solutions Inc. to address environmental concerns, as well as issues related to building space, fuel costs, comfort, reliability, and simplicity of operation.

The new boiler is located on the lower level of the Discovery Center, which requires heating for a minimum of nine months a year. Local wood densified into fuel pucks is delivered to an elevated walking-floor storage bin in a vestibule area built to protect against excessive moisture. (The biomass-fired boiler can burn any wood product with up to 50-percent moisture content.) An auger moves pucks from the storage area to a metering bin and into the boiler. Freezing is not an issue because the walking floor easily breaks up any frozen contents.

The boiler system was designed to highlight how biomass can reduce or eliminate the use of fossil fuels. Visitors can see the boiler operate through specially designed windows. In the hall just outside of the boiler room, the noise level and ambient temperature is consistent with the rest of the building.

Savings

Fuel costs have been cut by two-thirds. The densified pucks are used with almost no residual ash; eventually, however, tree clippings from the Ketchikan walking trails will be ground and fed into the boiler, eliminating the need for transport to a landfill, burning, and other methods of disposal.

The Boiler

The Hurst S100 Series Fire Tube 27 HP Hydronic Water Heating Boiler features a pre-heater to optimize combustion and an underfeed stoker with dry-ash-removal system.

Results

The system easily can be replicated for heat or heat/power generation up to 20,000 kw. In June 2011, Smith served as a keynote speaker for the fifth annual Native American Economic Development Conference in Anaheim, Calif., where he described the initiatives being implemented in Ketchikan and shared success stories of biomass-fired boiler systems installed on institutional campuses and in manufacturing facilities throughout the United States, particularly in challenging and remote locations. Systems include municipal solid waste, as well as woody biomass for steam production and steam to power.

RSS Feed

RSS Feed